Water is a critical part of the manufacturing process in most industries, which is why it is included in your water footprint, and why it needs to be managed effectively in order to ensure that environmental standards are met, water quality is reliable and there is no harm done to drinking water sources.

Water is a critical part of the manufacturing process in most industries, which is why it is included in your water footprint, and why it needs to be managed effectively in order to ensure that environmental standards are met, water quality is reliable and there is no harm done to drinking water sources.

Water usage varies considerably between developed countries and developing countries, with the United States, France, Germany, and Canada using the most water for industry and countries like India and Brazil, the call is for more water for agricultural needs.

Industrial water treatment processes include boiler water treatment and cooling water treatment, and when these treatments are not done correctly, it can lead to the reaction of solids and bacteria within pipes and the boiler housing. Steam boilers can suffer from scale or corrosion which can lead to weak and dangerous machinery.

Wastewater treatment removes most of the contaminants from sewage and wastewater, which produces a liquid effluent suitable for disposal to the natural environment as well as a sludge. Biological processes that are commonly used to treat wastewater include activated sludge, aerated lagoons, or slow sand filters.

Sewage must be conveyed to a treatment plant by appropriate pipes and infrastructure and the process must be adequately regulated because poor quality dirty water can become a breeding ground for bacteria.

Sustainable development is far more than just protecting the environment. The World Commission on Environment and Development (1987) stated that sustainable development is ˜development that meets the needs of the present without compromising the ability of future generations to meet their own needs.’

From an industrial perspective sustainable growth goals include reducing both resource consumption (e.g., water) and harmful environmental impacts. Industrial water management is a critical issue in making development sustainable.

The foundation of water resource management must be conservation, or reducing water use through improved operation of existing equipment and processes, including preventing scale, corrosion, and microbial formation.

With the proper treatment, a significant proportion of industrial on-site wastewater might be reusable.

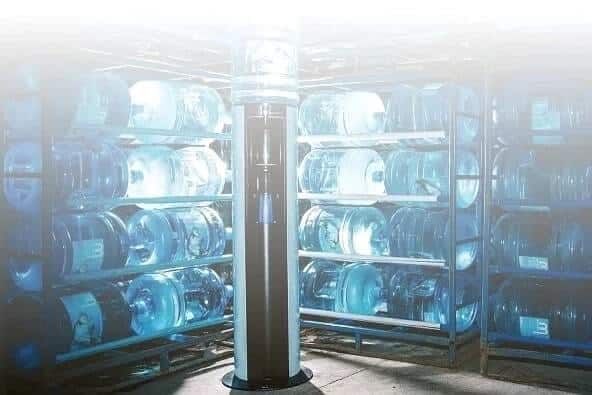

Get watercooler and plumbed water coolers from Living-Water in London.