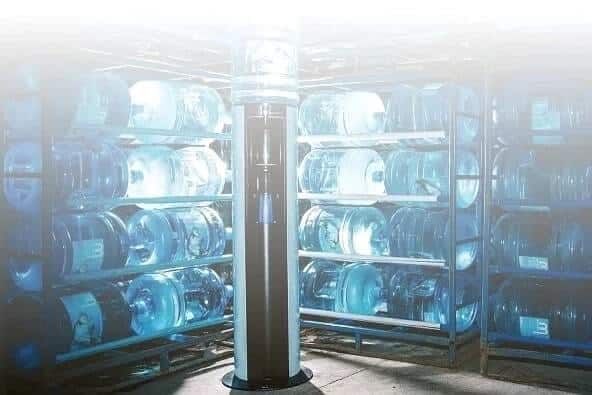

POU (Mains) Versus Bottled Water Coolers

POU (Mains) Versus Bottled Water Coolers

The last five years have seen a move in the industry towards POU coolers away from bottled. There are many reasons for this including just some of the below:

- Continuous delivery flow

- Environmentally friendlier (no transport required)

- Cost savings

- Building of new buildings/redevelopments pre-plumbed for POU solutions

As a result Living-Water covers both types of cooler but encourages:

- Supply direct chill coolers wherever possible – These coolers are the future of the industry and do not use the older reservoir type cooling systems which allow bacterial build-up within the reservoir. As a result it is widely accepted these coolers need less frequent sanitisation than the reservoir type coolers. It is our belief these coolers though a more expensive technology, should only be used wherever possible.

- Change POU filters on a minimum six monthly basis or more frequently as required. Sanitise all coolers on a 3 monthly basis

- Only use 1 micron filters

- Use flow blocks on all POU installations to prevent flooding

- Always fit a shut off valve on all POU installations

- To provide 48 hour servicing to all coolers in the event of problems or emergency deliveries

- All coolers must only use environmentally friendly gases.

- At the end of their working life, all coolers must be disposed off and recycled as far as possible in accordance with strict European legislation.

Ultimately it will always be the clients choice whether to adopt point of use water coolers – at Living-Water we can only consult a client on best practice and as a business, it makes little to no difference which product we supply – guaranteeing the optimum water delivery service will always remain our raison d’etre.